About the Process Metallurgy Module

A screenshot of the Process Metallurgy Module showing the evolution of the steel chemistry during ladle furnace treatment.

Designed for the Process Metallurgist

Questions the Process Metallurgy Module Can Help You Answer

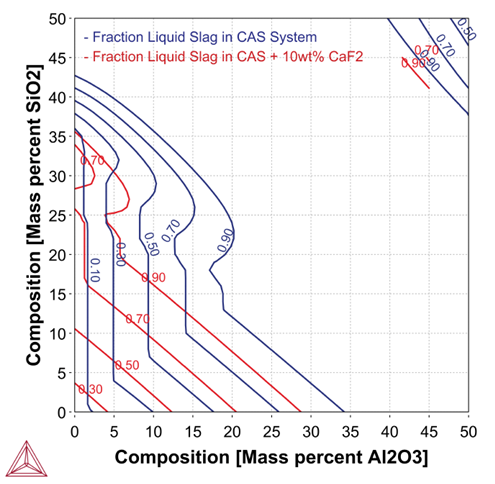

A plot from the Process Metallurgy Module showing the ratio of liquid slag to all slag in the system CaO-Al2O3-SiO2 (blue contour lines) and CaO-10 wt% CaF2-Al2O3-SiO2 (red contour lines) at 1600°C in equilibrium with a steel phase showing the extended liquid region on CaF2 addition.

The Process Metallurgy Module Allows You To

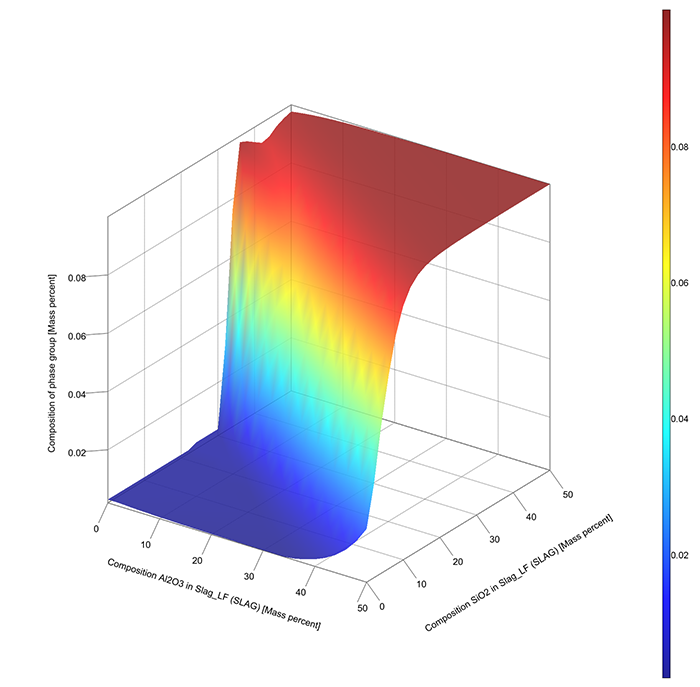

A plot from the Process Metallurgy Module showing the amount of sulfur in liquid steel in equilibrium with a CaO-Al2O3-SiO2 slag. The red colors in the upper right-hand corner at high silicon dioxide (SiO2) and aluminum oxide (Al2O3) contents show that the steel contains high amounts of sulfur. This means that only a little of the sulfur in the liquid steel partitioned into the slag phase and tells us that the slag phase has a poor capacity to take up sulfur. The blue colors in the lower left-hand corner indicate that the liquid steel contains only very low amounts of sulfur, so this would indicate a slag composition that is very effective at removing sulfur, or in other words, has a high sulfur capacity.

Easy Workflow for Steel and Slag Calculations

The Process Metallurgy Module makes it easy to define the composition of a steel and slag system because the calculator automatically provides the three common material groups—steel, slag, and gas— and provides default composition input types that are relevant to each material group.

You can save your material compositions right from the calculator and quickly access them in the future. For example, you might want to predefine compositions of steels, ferro-alloys, slags, and slag additions. The overall composition of the steel and slag is then obtained by simply adding amounts of these predefined materials.

The image shows the easy set-up of the different material compositions with the automatically provided material groups.

Full Integration into Our Software Development Kits

Application Examples

Learn More about the Process Metallurgy Module

Development of a computational thermodynamics EERZ model for the improvement of hot rolled light steel profiles steel refining

Simulating the Steelmaking and -Refining Process using Thermo-Calc’s Process Metallurgy Module

Several in-depth examples demonstrating how the Process Metallurgy Module can be used throughout the steelmaking process.

The Application of an Effective Equilibrium Reaction Zone Model Based on CALPHAD Thermodynamics to Steel Making

The Application of an Effective Equilibrium Reaction Zone Model Based on CALPHAD Thermodynamics to Steel Making

A Kinetic and Thermodynamic Description of the Steel Making Process using Thermo-Calc and the CALPHAD Database TCOX

A collection of videos demonstrating the capabilities of the Process Metallurgy Module.